Self build guide to low energy costs

2020 Architect Michael Howe provides an insight into sustainable technologies and materials which, when introduced to your self-build, can protect against spiraling energy costs and help future-proof your home.

The building envelope of your home is the first thing architects will look at. From the very onset, we look at techniques, technologies and materials which, when combined, will give homeowners the maximum efficiently within their budget.

Insulation is one of the most obvious points to consider. Most clients will select pump bead insulation into the cavity wall. If budget allows it however, then using Rigid Foil Faced PIR (Polyisocyanurate) or Rigid Foil Faced PUR (Polyurethane) insulation board in cavity walls is the way forward – running with either 150mm or 200mm.

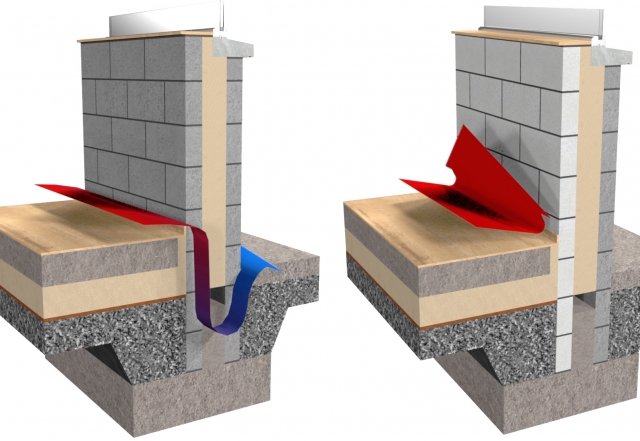

In order to increase thermal efficiency, it’s important to look at two things, the junctions and the wall ties to help reduce with thermal bridging. Using a wall tie that is manufactured from basalt fibers is an option for the wall ties as this will help reduce the thermal bridge between blockwork and insulation.

The other area is wall junctions themselves, where the floor and roof insulation meets the wall insulation. In traditional built homes, where the horizontal plane of insulation meets the vertical plane of insulation, there is no connection between the two and a thermal bridge can be created. This can be almost entirely eliminated by using an autoclaved aerated concrete block, also known as a thermal block.

Quinn Lite blocks are the most thermally efficient concrete block currently available throughout Ireland – and are 1000% more thermally efficient than a standard concrete block. Its excellent thermal performance eliminates heat loss caused by thermal bridging. Moreover, it can lead to a reduction in the amount of insulation required – hence saving on construction costs.

If you wish to have underfloor heating in your home, you would want to increase what’s known as the thermal mass of your floor. The efficiency of your underfloor heating can be maximised by using Ultraflo® screed – an innovative product by RTU. It is Ireland’s only ready mixed hemihydrate liquid floor screed.

The advantages of this screed are enormous. One of the major benefits is its fantastic performance with underfloor heating systems enabling heat to be transmitted to the room approximately 6 times faster than with sand and cement screed. This is due to the fact that the heating pipes are encapsulated with Ultraflo® to a depth of only 50mm compared to 100mm with non-compacted sand and cement screed.

Mechanical Heat Recovery Ventilation (MHRV) reduces heat loss as it avoids the need to open windows or install noisy extractor fans. Supplied and fitted by Daly Renewables, it works by extracting warm, moist air from bathrooms, shower rooms and kitchens via a system of ducting which passes through the heat via the exchanger into habitable rooms in the house such as bedrooms and living rooms.